Quality Assurance

Comprehensive inspection reports serve as a testament to the quality and integrity of machined and turned parts. These reports provide detailed documentation of inspection results, including dimensional data, surface analyses, and compliance records, offering transparency and peace of mind to customers.

Precision Starts with Inspection

Dimensional Accuracy

In CNC machining and turning, the smallest deviation from design specifications can lead to significant issues. At SMW, our inspection ensures that each component meets precise dimensional requirements, guaranteeing that each component meets precise requirements for fit and function.

Regulatory Compliance

Industries like aerospace, automotive, and medical devices have stringent regulatory requirements. Inspection and quality control procedures ensure compliance with industry standards and regulations, fostering trust and reliability in the manufactured parts. Our inspection protocols ensure that all components meet industry standards and regulations.

Surface Finish

The surface finish of machined and turned parts not only affects aesthetics but also impacts functionality and performance. Our Advanced Inspection techniques like surface profilometry ensure that surface roughness and texture meet desired standards, enhancing product quality.

Tolerance Verification

CNC machining and turning often involve tight tolerances. Through meticulous inspection, we verify that parts adhere to specified tolerances, preventing errors and ensuring seamless integration within assemblies.

In-Process Monitoring

Real-time monitoring of machining parameters allows us early detection of deviations from the desired specifications, enabling prompt adjustments to maintain quality standards.

Robust Process Planning

Thorough our process planning, including tool selection, machining parameters, and fixture design, lays the foundation for achieving quality and precision in CNC machining.

Quality Management Systems

Implementation of quality management systems, such as ISO 9001, fosters a culture of quality and continuous improvement within the organization, ensuring consistency and reliability in CNC machining operations. SMW follows stringent quality management systems, including ISO 9001, to ensure consistency and reliability in our machining operations.

Our Process

360-degree inspection on every single component manufactured

At Supreme Metal Works (SMW), we study the feasibility of every manufactured product as per AS 9100 standards. A detailed report is generated for the manufacturing and inspection of every component which facilitates a smooth flow of productivity and quality. Our clients can reliably depend on us for a consistent supply of quality and quantity.

- Laser Scanner

- Spectrometer

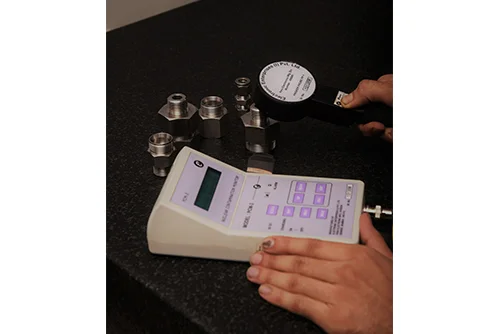

- PMI

- Tensile Testing

- Multi-bench Hydraulic Testing Facility

- Digital comparators

- Industry-endorsed plug, ring & thread gages

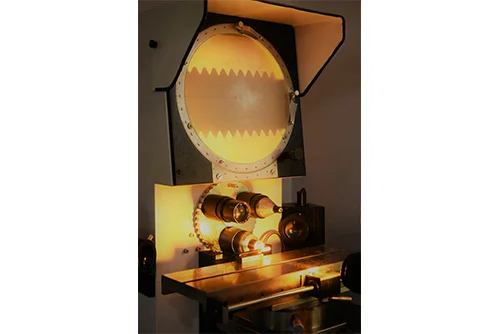

- Shadowgraphers

- Digital height indicators

- Profilometer

- Full stack of precision micrometers, calipers, and surface plates

- Hardness Testing Equipment

- Starrett Digital Video System

- Keyence optical comparators