CNC Machined Components Manufacturer in India

At SMW Precision Engineering, we specialize in providing high-quality precision manufacturing solutions tailored to meet the unique needs of our clients. With a commitment to excellence and a passion for innovation, we offer a comprehensive range of services including turned parts manufacturing, CNC machining, and much more.

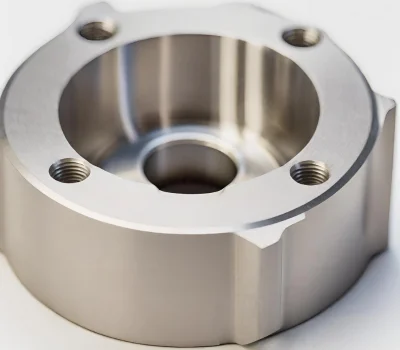

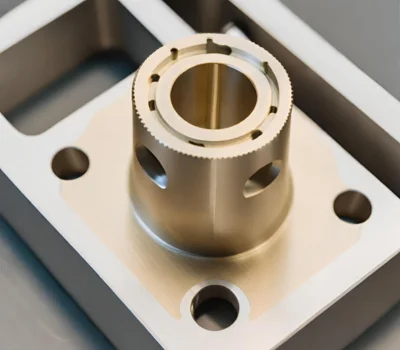

Precision Turned Parts Manufacturing

Our precision turned parts manufacturing service is equipped to handle projects of all sizes and complexities. With state-of-the-art CNC turning technology and a team of skilled professionals, we deliver components with unparalleled accuracy and consistency

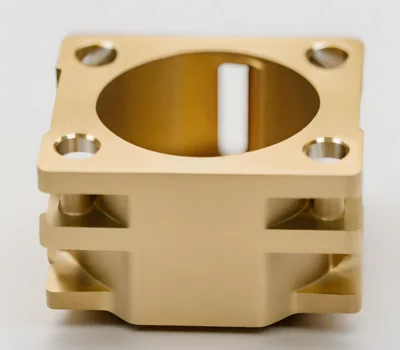

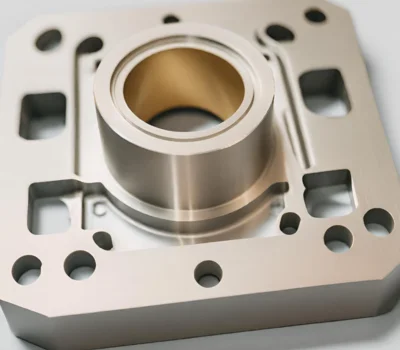

Advanced CNC Machining Service

From milling to drilling to tapping, our advanced CNC machining capabilities enable us to fabricate intricate geometries with precision and efficiency. Whether you need prototyping or high-volume production, we have the expertise and resources to fulfill your requirements

Mechanical Assemblies

In addition to our machining capabilities, we offer mechanical assembly services to streamline your manufacturing process. Our skilled technicians meticulously assemble components to your specifications, ensuring seamless integration and functionality

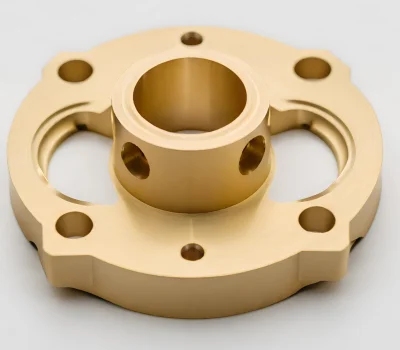

Customized Solutions

We understand that every project is unique, which is why we offer customized solutions tailored to your specific needs. From design optimization to material selection to production planning, we work closely with you to ensure your objectives are met with precision and excellence

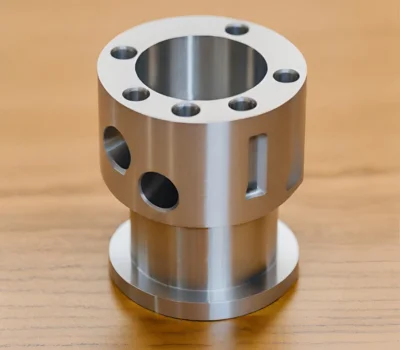

Manufacturing Engineering & Tooling Solutions

Manufacturing engineering and precision tooling solutions tailored to meet your unique needs. Our team of experts is dedicated to delivering top-quality results that drive efficiency and innovation in your production processes. Whether you require advanced machining techniques, custom tooling designs, or strategic manufacturing consulting, we're available to exceed your expectations.

One Single Source Solution for All your Engineering Works

Our engineering solutions offer a one-stop-shop for all your project needs. We handle everything from initial design to final implementation, using the latest technology and rigorous processes to ensure top-notch results. With us, you can rest assured that your project will be completed efficiently and effectively, saving you time and hassle.