What we do?

What benefits we deliver to our clients?

Leading engineering companies of India have worked with SMW to source their precision requirements and we have

delivered on time and with reliability without any exceptions.

What makes Supreme Metal Works trustworthy?

Proven Quality Systems: Certified QMS with strong PFMEA and process controls as per AIAG & VDA standards.

Consistent Delivery: High OTIF (On Time In Full) performance with a focus on reliability and commitment.

Precision & Compliance: Manufacturing aligned with aerospace and defense quality standards.

Advanced Infrastructure: In-house, fully equipped quality lab for testing, inspection, and validation.

Transparent Communication: Clear updates, documentation, and accountability at every stage.

Customer-Centric Approach: Long-term partnerships built on responsiveness and continuous improvement.

Client Struggles (Before SMW)

1. Inconsistent Quality & High Rejection Rates

Unstable processes, lack of PFMEA, and poor inspection systems.

2. Low On-Time Delivery (OTIF)

Delays and unpredictable supplier performance.

3. Multiple Vendors & Coordination Issues

Separate vendors for machining, coatings, and testing increase lead time.

4. Poor Documentation & Traceability

Missing inspection reports and process records

5. Limited Flexibility for Prototyping or Low Volumes

Suppliers avoid small-batch or development jobs.

How SMW Delivers Positive Outcomes

1. Consistent Precision & Quality

QMS-driven manufacturing, strong PFMEA, and in-house testing ensure single-digit PPM levels.

2. Reliable, On-Time Deliveries

Streamlined production and scheduling systems achieve OTIF above 95%.

3. Single-Source Manufacturing Partner

Machining, surface treatments, and testing under one roof reduce lead time by 20–30%.

4. Complete Traceability & Compliance

Comprehensive documentation aligned with aerospace and AIAG/VDA standards.

5. Agile & Responsive Support

High-mix, low-volume, and prototyping capabilities enable faster R&D and quick turnarounds.

What Makes Our Solution Stand Out

At Supreme Metal Works we are committed for Precision, Excellence and Quality

End-to-End Manufacturing Solutions

From precision machining to coatings, testing, and assembly — all under one roof for complete control and faster delivery.

Aerospace-Grade Quality Systems

QMS-driven operations, PFMEA as per AIAG & VDA standards, and traceability ensuring single-digit PPM performance.

Agile & Customer-Focused Approach

Flexible, responsive, and collaborative — we adapt to each client’s needs for high-mix, low-volume, and prototype requirements.

Our Services

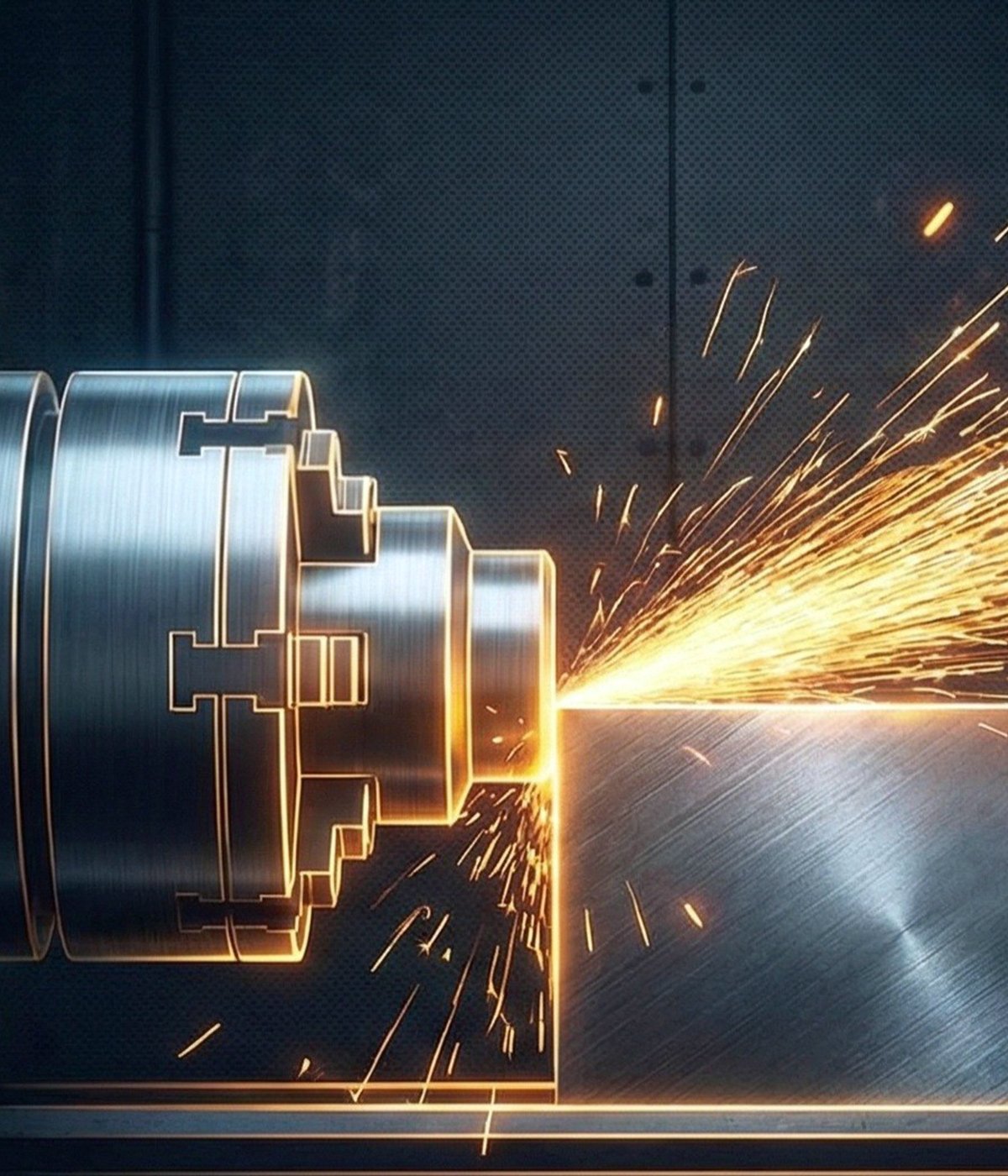

Precision Machined Components

From prototypes to production, our precision machined components deliver tight tolerances and reliable performance across aerospace, defence, automotive, and industrial sectors.

Sub-Assembly & Precision Assembly

We offer complete sub-assembly and precision assembly solutions engineered for accuracy, reliability, and seamless integration into your final products.

Tube Fittings

Single & Double ferrule tube fittings are manufactured in Stainless steel or Exotic materials conforming to international standards and customer specifications.

Sectors We Serve

N.D.A Non Disclosure Agreement

Supreme Metal Works attaches great importance to and protects the intellectual property rights of its customers and rejects any counterfeiting and copying. We undertake not to disclose any information such as drawings, manufacturing techniques and customer details to third parties.