Quality Assurance

How We Ensure Excellence from Start to Finish

Understanding & Planning

Client Requirement Analysis: Detailed review of drawings, specifications, and quality expectations.

Feasibility & Process Planning: PFMEA and process flow design as per AIAG & VDA standards.

Resource Allocation: Material, tooling, and manpower planned for precision and timeliness.

Execution & Manufacturing

Controlled Production : CNC machining, surface treatment, and assembly under strict process parameters.

In-Process Inspection : Stage-wise checks and real-time data monitoring ensure consistency.

Tooling & Calibration Management : Regular maintenance and verification to prevent variation.

Quality Validation & Delivery

Comprehensive Testing: Dimensional, surface, and performance testing in our in-house quality lab.

Final Inspection & Documentation: 100% traceability with inspection reports and certifications.

On-Time Delivery: Optimized scheduling and logistics achieving OTIF > 95%.

Continuous Improvement & Feedback

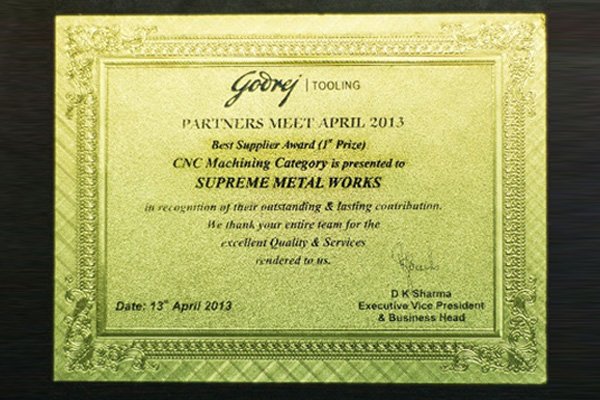

Performance Review: Regular internal and client feedback sessions.

Root Cause Analysis (RCA): Corrective and preventive actions for every deviation

Ongoing Optimization: Kaizen and Lean practices drive process and cost improvements.

Accountability & Transparency

Defined Ownership:

Each project assigned to a dedicated project manager and process owner.

Digital Tracking:

Job cards, inspection logs, and delivery milestones recorded systematically.

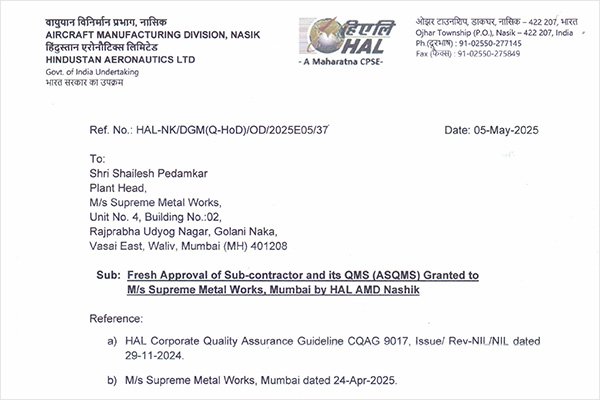

Audit-Ready Documentation:

Every step traceable to maintain accountability and compliance.

Tools, Techniques & Checkpoints

PFMEA, Control Plans, and Process Audits ensure proactive risk management.

SPC (Statistical Process Control) and CMM-based inspection for precision validation.

Internal Quality Gate System – No part moves to the next stage without approval.